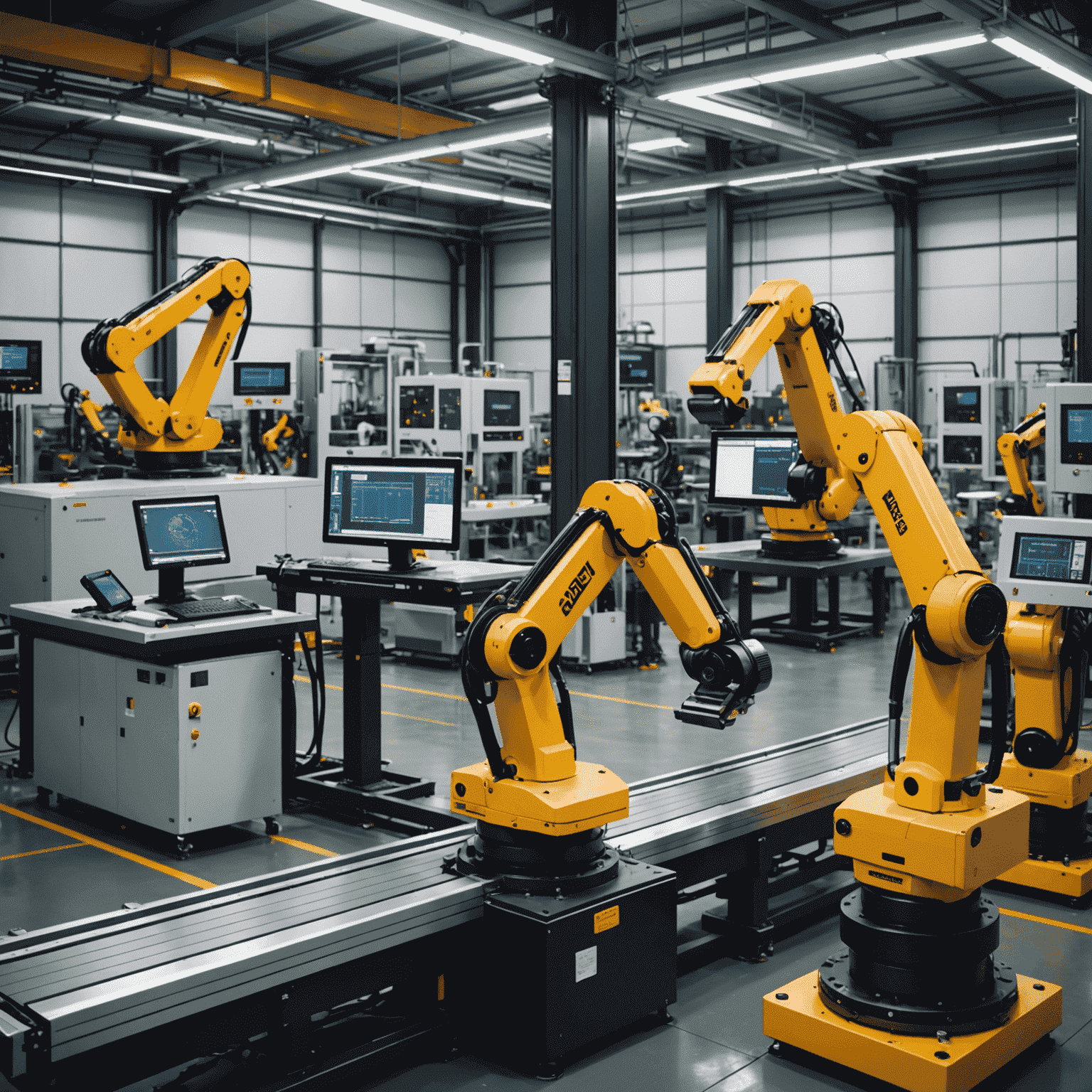

Sensor Technology Innovations Driving Smart Factories

The landscape of manufacturing is rapidly evolving, with sensor technology at the forefront of this industrial revolution. Smart factories are leveraging cutting-edge sensors to collect and analyze data in real-time, optimizing production processes and boosting efficiency like never before.

The Rise of Advanced Sensor Technologies

In the realm of industrial IoT and smart manufacturing, sensors are the unsung heroes driving the digital transformation. These sophisticated devices are capable of measuring a wide array of parameters, from temperature and pressure to vibration and chemical composition. Let's explore some of the groundbreaking sensor technologies that are revolutionizing factory floors:

1. MEMS Sensors

Micro-Electro-Mechanical Systems (MEMS) sensors are miniature marvels that combine mechanical and electrical components. These tiny devices are capable of detecting motion, orientation, and environmental conditions with incredible precision. In smart factories, MEMS sensors are used for equipment monitoring, predictive maintenance, and quality control.

2. Optical Sensors

Advanced optical sensors are bringing machine vision to a new level. These sensors use light to detect and measure various properties of objects on production lines. From identifying defects in products to guiding robotic arms with pinpoint accuracy, optical sensors are enhancing quality assurance and automation in manufacturing processes.

3. IoT-Enabled Smart Sensors

The integration of IoT capabilities into sensors has created a new category of "smart sensors." These devices not only collect data but also have the ability to process information at the edge, communicate wirelessly, and make autonomous decisions. Smart sensors are the backbone of industrial connectivity, enabling real-time monitoring and control of factory operations.

Real-Time Data Analysis: The Game Changer

The true power of modern sensor technology lies in its ability to provide real-time data for immediate analysis and action. This capability is transforming how factories operate:

- Predictive Maintenance: By continuously monitoring equipment performance, sensors can predict potential failures before they occur, reducing downtime and maintenance costs.

- Energy Optimization: Real-time energy consumption data allows for dynamic adjustments to factory operations, leading to significant energy savings and reduced carbon footprint.

- Quality Control: Instant feedback from sensors enables immediate corrections in production processes, ensuring consistent product quality and reducing waste.

- Supply Chain Visibility: Sensors tracking inventory and logistics provide up-to-the-minute information on material flow, optimizing supply chain management.

The Future of Sensor Technology in Manufacturing

As we look to the future, the potential for sensor technology in smart factories is boundless. Emerging trends include:

- AI-Enhanced Sensors: The integration of artificial intelligence with sensor technology will lead to even smarter decision-making and autonomous operations.

- Nanosensors: These microscopic sensors promise to revolutionize quality control and material science in manufacturing.

- Biodegradable Sensors: As sustainability becomes increasingly important, eco-friendly sensors will play a crucial role in responsible manufacturing practices.

The sensor technology innovations driving smart factories are not just improving efficiency and quality; they're reshaping the entire manufacturing landscape. As these technologies continue to evolve, they will undoubtedly play a pivotal role in the ongoing digital industrial transformation, pushing the boundaries of what's possible in modern manufacturing.